We prioritize both Means of Operator Protection (MOOP) and Means of Patient Protection (MOPP), incorporating measures like reinforced insulation, protective earth connections, and stringent leakage current limits to minimize the risk of electrical hazards.

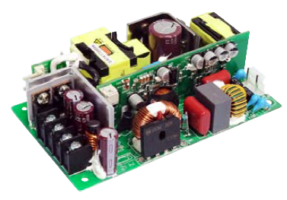

Medical Grade Power Supplies

The reliability of medical devices is essential and critical. Wall Industries’ medical-grade power supplies are designed to deliver safe, stable, and efficient power to all your essential medical equipment, from portable diagnostic tools to high-powered imaging systems. Whatever your needs, our commitment to quality and safety ensures your medical devices have the power they need to function flawlessly when it matters most.

Powering safe and reliable healthcare services

Medical power supplies demand the highest standards of safety, reliability, and performance to safeguard those using the equipment. A wide range of safety measures needs to be adopted in order to ensure medical power supplies meet all required compliances, such as IEC 60601-1. At Wall Industries, we’re committed to delivering carefully engineered and thoroughly tested medical-grade power solutions to meet these complex demands.

Prioritizing patient and operator safety

In the healthcare industry, safety comes first. Wall Industries' medical power supplies adhere to the highest safety standards, including IEC 60601-1, to ensure reliable and safe operation in critical medical settings.

Tailored solutions for a range of medical devices

Wall Industries offers a diverse selection of medical-grade power solutions designed to meet the specific needs of your healthcare applications.

Whether you need a compact, low-power supply for a portable heart rate monitor or a high-power, multi-output solution for a CT scanner, we have the perfect fit for your requirements.

Our external AC/DC power supplies are available in convenient wall-mount and desktop configurations, while our internal AC/DC power supplies are available in variety of form factors that can seamlessly integrate into your application.

For DC/DC converters, we offer both surface mount and through-hole options, providing much-needed flexibility.

Features

- 1W to 600W output power

- Single and multiple output options

- Separation of input and output circuits for reliable operation and safety

- Flexible mounting options to fit a wide range of medical devices

- AC/DC power supplies and DC/DC converters in various power ratings and configurations

- Certified to IEC 60601-1 medical safety standards, ensuring patient and operator protection

- Wide operating temperature ranges available

Applications

Find a Medical Power Supply Solution

Our diverse range includes hundreds of product families, easily searchable by voltage, power, format and application.

Search Medical Grade Power Supplies

Reliability and performance as standard

Wall Industries' medical power supplies are engineered for long-term reliability and consistent performance, ensuring that your medical equipment operates flawlessly for the long term.

Features like high efficiency, low ripple, and thermal management contribute to dependable power delivery, minimizing the risk of unexpected downtime or malfunctions that can prevent you from delivering a high-quality healthcare service.

Customizable power supplies for every situation

From critical care units in hospitals to home healthcare environments, Wall Industries provides power solutions for a wide range of medical applications.

Whether it’s a portable ultrasound machine, a vital signs monitor in the ICU, a home dialysis unit, or a complex surgical robot, our medical-grade power supplies ensure the seamless operation of essential equipment. And if your needs are unique, our experienced engineers have the expertise to design and manufacture custom solutions tailored to your specific requirements.

| Series | Input Range |

Input Voltage |

Output Voltage |

No. Outputs |

Output Power (W) |

|

|---|---|---|---|---|---|---|

PSSNP-Y11 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: -12, -5, 3.3, 5, 12, 15, 24, 48 | No. Outputs: S, D, T, M | Output Power (W): 110 | Get a QuoteDownload Datasheet |

The PSSNP-Y11 series of AC/DC open frame power supplies offers rated output power of 110 watts and peak output power of 160 watts in a 6” x 3.5” x 1.42” package. | ||||||

PSMHBU250 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 85~264 | Input Voltage: 100/240 | Output Voltage: 12, 15, 19, 24, 30, 36, 48 | No. Outputs: S | Output Power (W): 120, 250 | Get a QuoteDownload Datasheet |

The PSMHBU250 series of AC/DC medical and ITE power supplies offers 150 watts full load at free air convection, 250 watts with 8CFM forced air, and peak power of 300 watts. | ||||||

PSMBU123 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~260 | Input Voltage: 115/230 | Output Voltage: 5, 12, 19, 24, 36, 48 | No. Outputs: D | Output Power (W): 123, 125 | Get a QuoteDownload Datasheet |

The PSMBU123 series of AC DC open frame medical power supplies offers up to 125 watts of output power in a 6” x 3.50” x 1.46” unit. | ||||||

DTMPU130 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~260 | Input Voltage: 115/230 | Output Voltage: 12, 24 | No. Outputs: S | Output Power (W): 130 | Get a QuoteDownload Datasheet |

AC/DC Power Supplies - The DTMPU130 series of medical AC/DC approved power supplies provide 130 Watts of continuous output power. | ||||||

PSMBU152 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~260 | Input Voltage: 115/230 | Output Voltage: 12, 24 | No. Outputs: S | Output Power (W): 150 | Get a QuoteDownload Datasheet |

AC DC Power Supplies - The PSMBU152 series of medical AC DC power supplies provides 150W of output power in an open frame package. This series has single output models with a wide input range. This series has UL/cUL 3rd edition medical approvals. | ||||||

PSMBU153 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~260 | Input Voltage: 115/230 | Output Voltage: 12, 24 | No. Outputs: S | Output Power (W): 150 | Get a QuoteDownload Datasheet |

AC DC Power Supplies - The PSMBU153 series of medical AC DC power supplies provides 150W of output power in an open frame package. This series has ANSI/AAMI ES 60601-1: 2005 (UL/cUL 3rd ed) and EN 60601-1:2006 (TUV/T-mark 3rd ed) medical approvals. | ||||||

PSSNP-P15 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: 12, 15, 18, 24, 28, 36, 48, 5VSB | No. Outputs: D | Output Power (W): 154 | Get a QuoteDownload Datasheet |

The PSSNP-P15 series of AC/DC open frame medical power supplies offers rated output power of 154 watts, maximum output power of 185 watts, and peak output power of 220 watts in a 5” x 3” x 1.07” package. | ||||||

DTAM165 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: 12, 15, 19, 24, 28, 36, 48 | No. Outputs: S | Output Power (W): 160, 165 | Get a QuoteDownload Datasheet |

AC DC Power Supplies - The DTAM165 series of AC to DC desktop power supplies provides up to 165 Watts of output power. This series consists of single output models with a 90~264VAC input range and an IEC-320-C14 AC inlet. | ||||||

PSSNP-G16 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: 12, 15, 18, 24, 28, 36, 48 | No. Outputs: 12 | Output Power (W): 160 | Get a QuoteDownload Datasheet |

The PSSNP-G16 series of AC/DC open frame power supplies offers rated 160 watts, max. 240 watts, and a peak of 320 watts of output power in a compact 5” x 3” x 1.42” frame. | ||||||

DTHPU180A Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~260 | Input Voltage: 115/230 | Output Voltage: 12, 19, 24, 30, 33, 48 | No. Outputs: S | Output Power (W): 168, 180 | Get a QuoteDownload Datasheet |

The DTHPU180A series of AC DC medical desktop power supplies provides up to 180 watts of output power in a 7.40” x 3.52” x 1.94” package. | ||||||

What are Medical Power Supplies?

Medical power supplies are the AC/DC or DC/DC power supplies that keep medical equipment operational. They can be found in medical electrical equipment for both home and hospital use from handheld tools like thermometers to large equipment like MRI scanners.

As medical supplies have been advancing over the years, power supplies have become an increasingly more essential component to keep things running smoothly. As equipment has advanced, power supplies that keep them running have had to advance as well. Specifications have become more stringent to ensure the safety of both the operator of the equipment and the patient receiving care. Essential specifications include proper safety approvals, high MTBF and reliability, isolation, and high efficiency.

How are supplies designed for medical applications?

No matter the application, safety is a huge concern with any medical power supply. To be classified as a medical device power supply, compliance with IEC 60601 is required. Other factors like efficiency, MTBF, leakage, isolation, and reliability are crucial specifications to medical power supply. Due to these more stringent specifications, medical power supplies typically have a longer design cycle, but have a longer life expectancy.

Safety

The most important medical safety standard is IEC 60601-1. This standard outlines the basic safety requirements for electrical equipment used in a medical practice.

Efficiency

Efficiency in a power supply measures how much power is lost in the power conversion process. The less efficient a power supply is, the shorter its lifespan will be, so efficiency is crucial in medical applications.

Reliability/MTBF

Reliability is crucial for any medical power supply. Reliability ensures that a supply will continue to continue working for a long period of time and will not fail at a crucial moment. The higher the MTBF for a medical power supply, the better. Reliability is typically higher in supplies that have simple designs, but if this is not an option, reliability can also be improved through protection circuits, using high quality components, and conservative design practices. Bellcore/Telcordia TR-322 is an MTBF standard that can be applied to medical power supplies.

Isolation

Isolation is the separation of incoming high voltage (mains) to the low voltage output. Isolation helps prevent voltages from passing between components and can help prevent electrical shock and breaks ground loops. According to IEC 60601-1, medical equipment needs to isolate its circuits form the supply mains on all poles simultaneously and have very low leakage current.

Leakage

Leakage current is the current that still flows input to output during supply operation. It is important for leakage current in medical power supply to be low because any additional current that reaches the patient or the caregiver that is not intended to could cause serious harm. Leakage requirements in a medical power supply are determined by IEC 60601-1.

| Current | Description | Type B Applied Part | Type BF Applied Part | Type CF Applied Part | ||||

| Normal Conditions | Single Fault Conditions | Normal Conditions | Single Fault Conditions | Normal Conditions | Single Fault Conditions | |||

| Patient Auxiliary Current | DC | 10µA | 50µA | 10µA | 50µA | 10µA | 50µA | |

| AC | 100µA | 500µA | 100µA | 500µA | 10µA | 50µA | ||

| Patient Leakage Current | From patient connection to earth | DC | 10µA | 50µA | 10µA | 50µA | 10µA | 50µA |

| AC | 100µA | 500µA | 100µA | 500µA | 10µA | 50µA | ||

| Caused by an external voltage on SIP/SOP | AC | 10µA | 50µA | 10µA | 50µA | 10µA | 50µA | |

| DC | 100µA | 500µA | 100µA | 500µA | 10µA | 50µA | ||

| Total Patient Leakage Current* | With same type of applied part connected together | AC | 50µA | 100µA | 50µA | 100µA | 50µA | 100µA |

| DC | 500µA | 1000µA | 500µA | 1000µA | 50µA | 100µA | ||

| AC | 50µA | 100µA | 50µA | 100µA | 50µA | 100µA | ||

| DC | 500µA | 1000µA | 500µA | 1000µA | 50µA | 100µA | ||

*These values are only applicable to equipment having multiple applied parts.

Note: Above chart is based on information from IEC 60601-1 Ver. 3 and may not necessarily be the most current information.

To help reduce leakage current, medical power supplies should be properly grounded, double insulated or reinforced for to meet the requirements of the standard.

Shock

Shock is a huge risk when it comes to medical supplies because shock an electric shock from a power supply could severely harm a patient or caregiver. Means of Operator Protection (MOOP) and Means of Patient Protection (MOPP) laid out in IEC 60601-1 outline how supplies can be designed and tested to reduce the risk of electric shock to both the operator and the patient. Both MOOP and MOPP have to meet specific dielectric strength, creepage/clearance, and protective earth connection requirements to be certified as IEC 60601-1 and appropriate for medical devices.

Properly isolating components like the AC input, DC output, and the supply itself can help reduce the risk of shock and damage to the supply. Isolation is especially important around conductors.

Creepage/Clearance

Creepage and clearance in a supply offer space between conductive parts in a supply. Creepage measures this distance along the surface insulation, while clearance measures it through the air. It is important for medical equipment to have proper creepage to protect against deterioration caused by tracking, and proper clearance in order to prevent dielectric breakdown within the supply. Proper creepage and clearance also helps ensure compliance with MOOP and MOPP.

Minimum Creepage Distances and Air Clearances Between Parts of Opposite Polarity of the Mains Port

| Working Voltage – Up to and Including | Working Voltage – Up to and Including | Creepage Distance | Air Clearance |

| 17VDC | 12Vr.m.s. | 0.8mm | 0.4mm |

| 43VDC | 30Vr.m.s. | 1mm | 0.5mm |

| 85VDC | 60Vr.m.s. | 1.3mm | 0.7mm |

| 177VDC | 125Vr.m.s. | 2mm | 1mm |

| 354VDC | 250Vr.m.s. | 3mm | 1.6mm |

| 566VDC | 400Vr.m.s. | 4mm | 2.4mm |

| 707VDC | 500Vr.m.s. | 5.5mm | 3mm |

| 934VDC | 660Vr.m.s. | 7mm | 4mm |

| 1061VDC | 750Vr.m.s. | 8mm | 4.5mm |

| 1414VDC | 1000Vr.m.s. | 11mm | 6mm |

Minimum Air Clearances Providing MOOP from the Mains Part

| Working Voltage – Up to and Including | Nominal Mains Voltage ≤150V (Mains transient Voltage 1500V) | 150V < Nominal Mains Voltage ≤ 300V (Mains Transient Voltage 2500V) | 300V < Nominal Mains Voltage ≤600V (Mains Transient Voltage 4000V) | ||||||

| Voltage Peak or DC | Voltage r.m.s. (sinusoidal) | Pollution Degrees 1 and 2 | Pollution Degree 3 | Pollution degrees 1, 2, and 3 | Pollution degrees 1, 2, and 3 | ||||

| V | V | One MOOP | Two MOOP | One MOOP | Two MOOP | One MOOP | Two MOOP | One MOOP | Two MOOP |

| 210 | 150 | 1.0 | 2.0 | 1.3 | 2.6 | 2.0 | 4.0 | 3.2 | 6.4 |

| 450 | 300 | 1 MOOP 3.2, 2 MOOP 6.4 | 3.2 | 6.4 | |||||

| 840 | 600 | 1 MOOP 3.2, 2 MOOP 6.4 | |||||||

| 1400 | 1000 | 1 MOOP 4.2, 2 MOOP 6.4 | |||||||

| 2800 | 2000 | 1 or 2 MOOP 8.4 | |||||||

| 7000 | 5000 | 1 or 2 MOOP 17.5 | |||||||

| 9800 | 7000 | 1 or 2 MOOP 25 | |||||||

| 14000 | 10000 | 1 or 2 MOOP 37 | |||||||

| 28000 | 20000 | 1 or 2 MOOP 80 | |||||||

* Air clearances for working voltages above 20kVr.m.s. or 28 KVDC can be prescribed by particular standards if necessary.

Minimum Creepage Distances and Air Clearances Providing MOPP

| Working Voltage – Up to and Including | Working Voltage – Up to and Including | Spacing Providing One MOPP | Spacing Providing Two MOPP | ||

| Creepage Distance | Air Clearance | Creepage Distance | Air Clearance | ||

| 17VDC | 12Vr.m.s. | 1.7mm | 0.8mm | 3.4mm | 1.6mm |

| 43VDC | 30Vr.m.s. | 2mm | 1mm | 4mm | 2mm |

| 85VDC | 60Vr.m.s. | 2.3mm | 1.2mm | 4.6mm | 2.4mm |

| 177VDC | 125Vr.m.s. | 3mm | 1.6mm | 6mm | 3.2mm |

| 354VDC | 250Vr.m.s. | 4mm | 2.5mm | 8mm | 5mm |

| 566VDC | 400Vr.m.s. | 6mm | 3.5mm | 12mm | 7mm |

| 707VDC | 500Vr.m.s. | 8mm | 4.5mm | 16mm | 9mm |

| 934VDC | 660Vr.m.s. | 10.5mm | 6mm | 21mm | 12mm |

| 1061VDC | 750Vr.m.s. | 12mm | 6.5mm | 24mm | 13mm |

| 1414VDC | 1000Vr.m.s. | 16mm | 9mm | 32mm | 18mm |

| 1768VDC | 1250 Vr.m.s. | 20mm | 11.4mm | 40mm | 22.8mm |

| 2263VDC | 1600 Vr.m.s. | 25mm | 14.3mm | 50mm | 28.6mm |

| 2828VDC | 2000 Vr.m.s. | 32mm | 18.3mm | 64mm | 36.6mm |

| 3535VDC | 2500 Vr.m.s. | 40mm | 22.9mm | 80mm | 45.8mm |

| 4525VDC | 3200 Vr.m.s. | 50mm | 28.6mm | 100mm | 57.2mm |

| 5656VDC | 4000 Vr.m.s. | 63mm | 36mm | 126mm | 72mm |

| 7070VDC | 5000 Vr.m.s. | 80mm | 45.7mm | 160mm | 91.4mm |

| 8909VDC | 6300 Vr.m.s. | 100mm | 57.1mm | 200mm | 114.mm |

| 11312VDC | 8000 Vr.m.s. | 125mm | 71.4mm | 250mm | 142.8mm |

| 14140VDC | 10000 Vr.m.s. | 160mm | 91.4mm | 320mm | 182.8mm |

How are the standards for medical power supplies defined?

The standards for medical power supply units are primarily defined by the International Electrotechnical Commission (IEC). The primary medical safety standard that applies to medical equipment safety is IEC 60601-1, but CISPR 11: 2015 also covers some specifications for medical power supplies.

IEC 60601-1/UL 60601-1

This standard was originally published in 1977 and has since consisted of 4 updates, the most recent published in January 2020. This standard covers a variety of specifications that medical electronics need to meet and be tested against before they are used in hospital or home healthcare. Some of those standards include the following.

Environmental Tests

Medical equipment needs to be tested to meet proper temperature, humidity, and atmospheric pressure conditions as indicated by IEC 60601-1.

Protection against Electrical Hazards

IEC 60601-1 outlines protections and limitations that medical equipment will need to have for electrical hazards like shock, water/particulate matter, and leakage current. It also outlines the standards required for methods of protecting against electrical hazards like protective earthing, MOOP, MOPP, leakage, insulation, creepage and air clearances, and layout.

Protection Against Mechanical Hazards

Medical equipment needs to have proper protection against certain mechanical hazards such as moving parts, expelled parts, instability, acoustic energy and vibration, and pneumatic and hydraulic pressure. IEC 60601-1 addresses the hazards that are associated with these moving parts and how the risk created from moving parts coming in contact with one another can be reduced.

Protection Against Unwanted/Excessive Radiation

Medical equipment is prone to exposure to unwanted or excessive radiation, given the environment it is used in. IEC 60601-1 outlines radiation limitations for x-radiation, alpha, beta, gamma and neutron particle radiation, microwave radiation, infrared radiation, and UV radiation.

Classifications

Class

Class classification identifies protection against electric shock.

Class I: Powered by an external power source, reliable protective earth

Class II: Powered by an external power source, no reliable protective earth, reinforced insulation

Class IP: Internal power supply

Type

Type classification identifies the type of patient applied part or patient lead. It covers devices with circuitry or parts that will come into direct contact with patients.

Type B: Patient applied part earthed

Type BF: Patient applied part floating (surface conductor)

Type CF: Patient applied part floating or use in direct contact with the heart

CISPR 11: 2015

This standard applies to medical electrical equipment (as well as industrial and scientific equipment) that will be operating in the frequency range of 0-400GHz. It covers the limits and methods of measurement for radio frequency disturbance characteristics, as well as requirements to control RF disturbances.

How is a medical power supply different than a commercial supply?

Commercial supplies and a medically approved power supply differ primarily in their safety, reliability, and longevity. A standard commercial supply may not be compliant to IEC 60601-1, which is crucial for a medical power supply. A commercial power supply may also be lacking in the proper environmental protections, reliability ratings, and MTBF that are key specifications for a medical power supply.

A commercial power supply will also not have Means of Patient Protection or Means of Operator Protection. These two specifications are vital for medical supplies because they protect both the operator and the patient from shock that could cause serious harm. A standard, commercial supply may have protections against shock, but they will not be to the extent that MOOP and MOPP are approved for. This aligns itself with the safety criteria which is the major difference between commercial power supplies and medical power supplies.

Where are medical power supplies used?

Medical power supply units are used in electrical medical equipment in hospitals and home care. They can be either internal or external supplies and either AC/DC or DC/DC. Depending on the application, different medical power supplies will be needed and different specifications will need to be met.

Hospital

Hospitals need to be equipped with a wide range of electrical medical devices in order to care for a wide range of patients. Medical equipment for a hospital can include devices such as heart rate monitors, blood pressure monitors, ventilators, incubators, x-ray machines and CT scan machines, just to name a few. Medical power supplies play a vital role in helping this equipment functioning and working properly.

In-Home

Medical equipment for home care will typically be smaller in size and more suited to individual care than hospital grade equipment. Home medical equipment can include devices such as portable ventilators, sleep apnea machines, hearing aids, and different types of monitors and meters. Power supplies are used to keep these medical electronic devices running and can be found internally in devices or externally as chargers.

Who can design your medical power supply? Why is Wall the best choice?

As a medical power supplier, Wall Industries is here to ensure the highest quality supply for your medical application. We have standard open frame, wall mount, and desktop medical grade power supplies if AC/DC is needed, as well as surface mount and through hole options for DC/DC. We also offer extensive custom capabilities and have many years of experience designing highly efficient power sources that meet IEC 60601. Whether a medical supply is needed for hospital or home use, Wall can find something that will fit your specifications. Explore our solutions or get in touch with us today.

Does medical equipment require AC or DC power?

Medical equipment can require both AC and DC power, depending on the type of device and what it is being used for. Medical environments use a range of devices that have different power requirements, so it is important to get the right type of power supplies.

AC powered equipment can be plugged into a standard electrical outlet and run on the AC mains voltage. AC power will typically be used for medical devices such as X-Ray machines, hospital beds and other diagnostic equipment.

DC powered equipment tends to be portable and bettery operated, such as patient monitors and portable defibrillators.

How do I choose the right medical-grade power supply?

When choosing the right medical power supply for your application, it’s important to consider voltage output and current requirements, isolation, temperature range, efficiency and safety certifications.

Can PCB mount supplies be used in the medical industry?

PCB mount (Printed Circuit Boards) power supplies are used to power various medical devices and equipment due to their convenience and easy integration. PCB mount supplies are typically found in portable monitoring equipment, X-Ray systems, MRI equipment, ECG monitors, blood pressure monitors, labaratory instruments and therapeutic devices such as laser therapy machines.

Are medical power supplies used in dentistry settings?

Medical power supplies are designed to provide reliable and safe power for all medical devices and equipment, including those used in the dentistry sector. This includes powering equipment such as dentistry chairs, dental handpieces, scalers, lights, X-Ray systems, and sterilizing equipment.

Get a Quote

Request information for from Wall Industries.

"*" indicates required fields

Custom Solutions

Wall Industries, Inc. offers fully custom power design capabilities. Our team of electrical and mechanical power design engineers will utilize proven design topologies and concepts to create a solution to your power requirements. If you don’t have a specification, Wall’s engineering team will assist you in determining what your requirements are and how best to provide a solution.

Custom Power Supplies