EV Power Supplies and Converters

Find a diverse selection of electronic devices designed for electric vehicles. Our range of electric vehicle power supplies includes various types and topologies, each designed to meet specific requirements and applications including high-efficiency onboard chargers, off-board DC fast chargers, and battery management systems. Browse our collection to find the right electric vehicle power supply for your needs.

| Series | Input Range |

Input Voltage |

Output Voltage |

No. Outputs |

Output Power (W) |

|

|---|---|---|---|---|---|---|

PSEOCH05 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~305 | Input Voltage: 115/230 | Output Voltage: 3.3, 5, 12, 24 | No. Outputs: S | Output Power (W): 5, 5.04 | Get a QuoteDownload Datasheet |

The PSEOCH05 series of AC/DC ITE power modules offers up to 5.04 watts of output power in a very compact 1.46” x 1.08” x 0.69” package. | ||||||

PSAOD10 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: 5, 12, 15, 24 | No. Outputs: S | Output Power (W): 10 | Get a QuoteDownload Datasheet |

The PSAOD10 series of AC/DC ITE/Household power modules offers up to 10 watts of output power in small 1.46” x 1.08” x 0.79” PCB mountable package. | ||||||

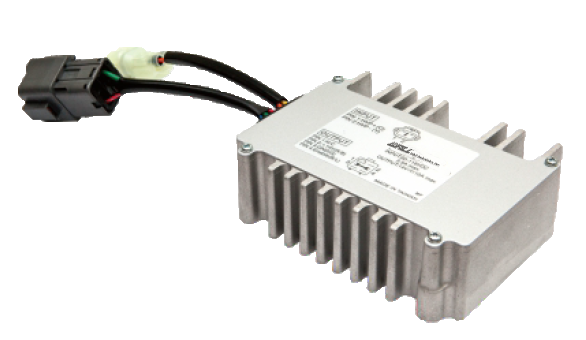

DCVK168 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 60~118 | Input Voltage: 70/110 | Output Voltage: 14 | No. Outputs: S | Output Power (W): 168 | Get a QuoteDownload Datasheet |

The DCVK168 series of DC/DC converters offers 168 watts of output power in a 4.76” x 3.79” x 1.44” package. | ||||||

PSAEK3000HV-OR Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 90~264 | Input Voltage: 115/230 | Output Voltage: 150, 200, 250, 300, 400 | No. Outputs: S | Output Power (W): 3000 | Get a QuoteDownload Datasheet |

The PSAEK3000HV-OR series of AC/DC switching power supplies provides 3000 Watts of output power in an 11.02” x 6.69” x 2.52” enclosed case. | ||||||

PSEV3600 Series Description: The PSAYC series of AC/DC switching power supplies provides 2 watts of output power in a 1.33" x 0.87* x 0.67* encapsulated PCB mountable package. | Input Voltage: 220 | Input Voltage: 220 | Output Voltage: 29.2, 42, 54.6, 71.4, 84, 29.4, 44.1, 58.8, 73.5, 88.2 | No. Outputs: S | Output Power (W): 3600 | Get a QuoteDownload Datasheet |

The PSEV3600 series of AC/DC battery chargers offers up to 3600 watts of output power in a 12.4” x 7.08” x 5.12” package. | ||||||

How Do Electric Vehicles Work?

Electric Vehicles (also known as EVs) can come in a number of configurations including hybrids, parallel hybrids, series hybrids, hydrogen fuel-cell cars and plug-in electric.

All cars (including conventional gasoline vehicles) perform a similar function: they are energy conversion devices which turn stored energy into kinetic energy.

Electric vehicles, and their many iterations, harness stored electric energy to either assist or solely power locomotion.

For example, parallel hybrid vehicles use energy from an on-board battery, as well as an internal combustion engine (ICE) to power locomotion.

Series hybrids draw on the electric motor to power the vehicle, when the battery runs low the ICE kicks in, driving a generator which recharges the battery.

Plug-in full electric vehicles, meanwhile, solely run off the stored energy in their batteries.

Key Electric Components In Electric Vehicles

The key electronic components in a full-electric vehicle are:

Electric motor – This is used to drive the rotation of the wheel. Typically an AC motor is used, however they can also be DC too. Electric motors differ greatly from gasoline engines, with a key differentiator being that they can provide instant torque.

Transmission – This transfers power from the electric motor to drive the wheels.

Battery – Most electric cars run off a large electric battery which consists of many smaller lithium-ion battery modules which are linked together in circuits designed to deliver the maximum power in the most efficient way.

Power electronic controller – This controls the speed of the motor (and the torque it produces) by managing the flow of electrical energy from the battery.

Onboard charger – This component takes the incoming power from a charge port and controls the charge placed on the battery optimizing the charge cycle.

DC/DC converter – This device steps down the higher-voltage DC power stored in the battery pack to the lower-voltage DC power that is required to recharge the auxiliary battery and power the vehicle’s on-board systems.

DC/AC Inverter – This crucial component converts the DC electricity stored in the battery to the AC needed to run the motor.

Thermal system – This regulates temperatures across the various systems in the vehicle, including the motor, power electronics and engine.

Electric Vehicle Power Converters and Inverters

Power converters and inverters play a key role in an electric vehicle, working in tandem to supply the vehicle’s separate systems with the correct type and level of power. The majority of electric and hybrid vehicles use two storage devices, with the main energy system providing power for long-distance driving and the secondary system providing acceleration and regenerative braking.

How DC-DC Power Converters Work In Electric Vehicles

Why do we use DC to DC converters in electric vehicles?

High-quality, efficient power converters are required for proper integration between the storage batteries and the traction drive. DC-DC converters are an integral component in an electric vehicle, chopping or boosting voltage levels in order to interface with the electric powertrain.

In order for DC-DC converters to be suitable for electric vehicle applications, components must be lightweight, reliable, be small in size and highly efficient. In order to function within the constraints of the automotive application, converters must also have low electromagnetic interference.

Which types of power converters are employed in electric and hybrid vehicles?

Two types of DC-DC power converters are typically used in electric vehicles: unidirectional DC-DC converters and bidirectional DC-DC converters. Unidirectional converters are used to assist onboard loads such as entertainment, utility, controls and safety systems. Meanwhile, bidirectional DC-DC converters are used for battery charging, backup power and regenerative braking applications.

Why is the motor drive in an electric car a bidirectional power converter?

Bidirectional power converters are required in electric cars in order to connect the battery to the DC link of the motor drive system. Electric vehicles typically function in three modes: acceleration mode, normal mode and regenerative mode.

During normal and acceleration modes, power is drawn from the battery to the motor, whereas regenerative modes require the kinetic energy from the motor to be converted into electrical energy and returned back to the battery.

How DC-AC Power Inverters Work In Electric Vehicles

Power inverters are required in electric vehicles in order to convert the high-current DC electricity into AC electricity that can be used for the motor. Inverters are electronic devices that make use of power transistors in order to slice DC signals into an AC output.

What does an inverter do on an electric car?

In simple terms, these power transistors switch on and off rapidly to change a DC output into a sine wave or pulse width modulated (PWM) shape. Additional filtering helps to further smooth the signal out until it comprises a purse sinusoidal AC output which can be used by an electric vehicle’s traction motor.

Do you need a special charger for electric cars?

You don’t need a special charger for an electric car. Plug-in electric cars can be charged using a standard 120-volt wall socket, this is referred to as Level 1 charging. Whilst this is easy to achieve, it takes a long time and will not be sufficient to charge a fully electric vehicle that is used on a daily basis.

Electric car owners also have the option of installing a 220V ‘Level 2 charging’ station at their homes that can charge at a quicker pace.

How many amps does an electric car need?

The majority of electric vehicles take approximately 32 amps, charging at a rate of 25 miles of range per hour (depending on the vehicle and driving conditions). However, 50-amp chargers are also available that add 37 miles of range per hour. The amount of amps your home has available for charging will dictate what charging station you’ll be able to install in your home.

How many watts does it take to power an electric car?

Electric cars have batteries with a capacity of between 24 to 100 kWh. A 24 kWh battery holds enough energy to supply 24,000 Watts for an hour. Taking energy costs at $0.15 per kWh, it would cost $3.60 to fill an empty 24 kWh battery which could give you a range of approximately 72 miles, depending on the vehicle and driving conditions.

Do electric vehicle charging stations require AC or DC power?

Charging stations can use either AC or DC power to charge electric vehicles, depending on the type of charging station that is required and the desired length of time to charge the vehicle.

There are two types of AC charging stations: Level 1 charging stations tend to be a household outlet, as they have a lower power outlet (120v) and offer a slower charging time. Level 2 charging stations have a larger power outlet (240v) and are commonly found at public charging stations such as supermarkets, and commercial buildings. DC charging stations offer high power DC charging for electric vehicles, offering a direct supply to the vehicle which allows for rapid charging. They are commonly found along highways, and high demand travel routes for drivers requiring power for their car.

Which type of power supply is useful for rapid electric vehicle charging?

For rapid electric vehicle charging, DC power is recommended due to it’s ability to meet large power requirements, efficiency and reliability in a short amount of time. This type of power supply is typically found at large commercial buildings or near highways, where rapid charging is important for drivers.

Do electric vehicle power supplies require water protection?

Electric vehicle power supplies typically require protection from water, especially when located in outdoor environments and are exposed to rain or snow. This is to avoid short circuits or electrical failure, prevent corrosion or damage to the power supply and provide enhanced safety for users.

How do I choose the right electric vehicle power supply?

When choosing the right electric vehicle power supply for your requirements, it’s important to consider the required voltage output, efficiency, input voltage compatibility and safety certifications. Wide temperature ranges, isolation, and low noise may also need to be considered when choosing an electric vehicle power supply.

Get a Quote

Request information for from Wall Industries.

"*" indicates required fields

Custom Solutions

Wall Industries, Inc. offers fully custom power design capabilities. Our team of electrical and mechanical power design engineers will utilize proven design topologies and concepts to create a solution to your power requirements. If you don’t have a specification, Wall’s engineering team will assist you in determining what your requirements are and how best to provide a solution.

Custom Power Supplies