Advances in technology have led to electronics, electrical systems, and power supplies getting smaller over time. This opens up new options for businesses, providing additional design space and improving overall efficiency.

Reducing the size of an AC-DC power supply isn’t as straightforward as you might think. Designers need to select components and utilize topologies which maximize space without compromising safety or performance.

Regardless of size, end user systems require dependable power supplies that are industry appropriate. In this article, we discuss the challenges and design solutions for creating compact power supplies for use in a range of different industries.

Importance of Compact Designs for Power Supplies

Throughout the 21st century, we’ve seen the size of many commercial electronic devices decrease, largely due to the availability of more compact components. A leading factor for this has been the demand for smaller more compact equipment in all areas of electronics. Higher component density is the only way to achieve this.

Compact power supply design enables more than just innovation. As systems become more complex and demanding, power supply designers must prioritize smaller designs to ensure a unit fits within existing infrastructure. These space-saving considerations should be made at each stage of the design process.

Key US industries and applications with strict space requirements:

- Aerospace

- Robotics

- Military

- Railway

- Medical

Design Challenges When Minimizing Size in AC-DC Power Supplies

Although the demand for more compact power supply design is high, especially with the rise of data centers for powering various AI processes, it’s not straightforward. The challenge is maintaining the supply’s capabilities, protections, safety features, reliability, and industry applications while reducing its overall size. Each time the size is reduced, it intensifies the engineering design work associated with the power supply to ensure functionality.

The main challenges can be broken down into the following areas:

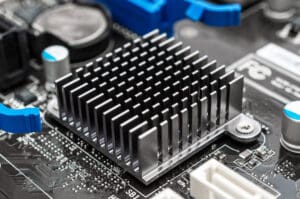

- Thermal management in small enclosed spaces

As power density increases, so does heat density. This is because, with smaller physical footprints, there’s less surface area to dissipate heat. This is especially apparent in fully sealed or rack-mounted systems. Whatever the application, power supplies must prevent hotspots by ensuring uniform heat distribution.

If you put more power into a smaller volume, which yields a smaller footprint against the heat sink, you have a smaller transfer area for that heat to be conducted out of the unit and into the heat sink and then the air. It is just like trying to force a liquid through a funnel. The funnel may hold a certain volume of liquid but it is limited to how fast it can transfer that liquid into the end container. Air in this case is the end container and the flow of heat from the device is going through the proverbial neck of a funnel. There are physical limitations to how well any heat sink can transfer that thermal energy away from the device. This goes back to how much thermal rise you can allow your components to withstand.

- Maintaining isolation and meeting safety standards

Isolation barriers ensure safe operation, particularly in medical, industrial, or high-voltage applications. As size shrinks, maintaining appropriate creepage and clearance distances becomes more difficult.

Safety standards can vary across industries, so engineers need to consider compliances required for end applications. For example, the IEC 60601 standard is for medical electrical equipment, the IEC 62368 is for industrial and information technology, and there are various MIL-STD standards governing the manufacture of power supplies for military applications. These standards dictate different creepage and clearances which must be maintained.

- Minimizing EMI without bulky components

(EMI) filtering and suppression can be challenging when faced with higher switching frequencies. This becomes a common issue as high switching frequencies are used to increase system efficiency. If you are carrying high levels of current it exacerbates this problem. In compact designs, this challenge becomes more prominent as there isn’t space for traditional filtering features such as common-mode/normal mode chokes. Controlling EMI isn’t just vital to protect the functionality of the end user systems, it must also be done to meet global EMC standards.

- Designing for industry standards

Standards for safety, performance, and specific features will differ depending on the industry and end application. Compact power supplies already come with design constraints, by adding more requirements to the design, it ultimately introduces more complexity and additional costs. It’s also important to note that each industry may have multiple standards to comply with.

Solutions

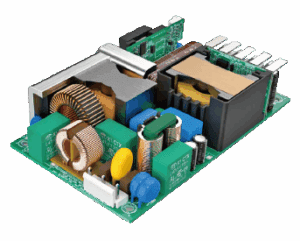

Designers must focus on a topology that fits the space constraints and overall goals of the end user systems, while also minimizing space. The main areas where size can be minimized within an AC-DC power supply are:

- LLC – the use of an LLC offers zero current and/or voltage switching. This means there is no sharp rise and falls of switching voltages, which minimizes the need for EMI filtering.

- Power factor correction (PFC) circuits – forgoing the need for a snubber circuit can save on 5 or 6 components. This can be possible through the use of silicon carbide diodes, or diode-less designs (the use of FET’s as rectifiers) although it will be necessary to check the financial feasibility of sourcing these parts at the time they’re needed.

- Control circuits – although more expensive, integrated control circuits will result in fewer components and more board space. This is why we are seeing power supplies using more digital circuitry.

- Input filter – using cores with high-permeability will minimize the size of the filter without compromising noise reduction. Further space-saving can be achieved through the vertical positioning of components.

- Primary converter – proper resonant topology here can eliminate switching losses to a large degree. As a result, designers can get away with using smaller heat sinks

- Output rectifier – again, this is a case where increasing efficiency can allow for a more compact design. Synchronous rectification using MOSFETS can lead to a significant reduction in power dissipation.

- Efficient encapsulation – Some power supplies must be encapsulated to provide reliable power in harsh environments. Using a highly thermally conductive material as an encapsulant, space can be saved with the right design and material choices.

LLC Resonant Supply Design

Resonant LLC converters are an effective option for meeting the performance demands of modern power supplies without increasing size. These topologies allow for higher switching frequencies while also reducing switching losses. As LLC designs don’t require an output inductor, all inductors in the system can be consolidated into a single magnetic structure to further save space and cost.

Examples of Compact AC DC Power Supplies

The Wall Industries’ range of AC DC converters contains many examples of solutions that supply power with a compact footprint. We’re constantly working to design innovative power supplies in smaller package sizes across a variety of applications.

The following are examples of small standard power supplies in our product offering. Through custom designs, even smaller footprints can be achieved. Sourcing a custom power supply design is the best way to ensure the dimensions of your power supply are appropriate for your end systems. Custom power supplies are also guaranteed to integrate with your existing infrastructure.

- 0.77“ x 0.39“ x 0.49“ SIP-7 package

- 2 Watts

- Dual output models, performance optimized for IGBT/SiC

- 6000VDC isolation

- UL62368 certification

- 1.33“ x 0.87“ x 0.67“

- 2 Watts

- Single output models with 90~305VAC universal input range

- Fully encapsulated plastic case

- UL/cUL, CE, and CB safety approvals

- 1.46“ x 1.08“ x 0.69“

- 5 Watts

- Single output models with 90~305VAC universal input range

- 4000VAC isolation

- Meets safety approvals for IEC/EN 60335-1, UL/IEC/EN 62368-1, IEC/EN 60950, and IEC/EN 61558-2-16

- 1“ x 1“ x 0.64“

- 3 Watts

- Single output models with 85~264VAC universal input range and no minimum load requirement

- Fully encapsulated plastic case for PCB mounting

- RoHS and REACH compliant

- UL/cUL/IEC/EN 60950-1 and TUV/IEC/EN 60335-1 Safety Approvals & CE Marking

- 5“ x 3“ x 1.09“

- 600 Watts

- Single output models with 85~264VAC universal input range

- Optional 5V Standby + Remote ON/OFF

- IEC 62368-1 Edition 2.0, IEC 62368-1 Edition 3.0, EN 62368-1, UL62368-1, CAN/CSA-C22.2 NO.62368-1, IEC 60601-1 Edition 3.1, IEC 60601-1 Edition 3.2, EN60601-1, ANSI/AAMI ES60601-1, CAN/CSA-C22.2 NO. 60601-1 Safety Approvals

- 5“ x 3“ x 1.5“

- 600 Watts

- Single output models with 85~264VAC universal input range

- Optional 5V Standby + Remote ON/OFF

- IEC 62368-1 Edition 2.0, IEC 62368-1 Edition 3.0, IEC 60601-1 Edition 3.1, IEC 60601-1 Edition 3.2, EN 62368-1, EN60601-1, UL62368-1, CAN/CSA-C22.2 NO.62368-1, CAN/CSA-C22.2 NO. 60601-1, ANSI/AAMI ES60601-1 Safety Approvals

Conclusion

Compact power supplies pose a significant challenge to designers. However, due to increased demand and innovations in other technologies, creating smaller power supplies is going to become more common.

Size reduction should never come at the cost of efficiency, safety, or reliability. With the right design approach and engineering partner, you can achieve compact AC-DC power supply solutions that meet modern expectations in even the toughest environments.

At Wall Industries, we combine 6 decades of experience with cutting-edge materials and design approaches to meet the challenge of compact power supplies head-on. Get in touch to discuss your project requirements.