How power supplies help industrial robotics function and why choosing the right one is so important.

Industrial robotics has revolutionized the way we build everything from smartphones and medical devices to cars and airplanes. By replacing or augmenting human activity across the manufacturing process, robots have enabled a huge increase in productivity and efficiency. And we are still only at the very beginning of what may be possible.

Of course, like any advanced technology, industrial robotics relies on an efficient and reliable source of power to function effectively. Without the right power supplies, industrial robotics won’t deliver the benefits you’re expecting.

In this article, we’ll look at the wide variety of industrial robots that play a vital role in today’s manufacturing processes. We’ll also outline the importance of power supplies for industrial robotics, and set out some key points to help you find the right power supply for your needs.

What is industrial robotics and what is it used for?

Industrial robotics refers to the vast range of autonomous tools used in the world of manufacturing. These tools help make industrial processes faster, more efficient, and more precise.

Industrial robots are most commonly a moveable arm with multiple axes or small mobilized robotic vehicles. This robotic hardware is accompanied by automation software that allows the industrial robot to perform a variety of different tasks in place of a manually operated machine or a human. Industrial robots assist manufacturers in improving safety, efficiency, ease of use, and precision across various complicated operations.

Industrial robots are typically installed to accomplish a specific process or application that helps the manufacturing process. Some of the most common processes include material handling, automated guided vehicles, sorting systems, palletizing robots, among other developing manufacturing technologies. As technology continues to advance and change, industrial robotics evolves as well and adapts to new processes and applications.

What are the different types of industrial robots?

Based on their mechanical structure, “arm type” industrial robots can be classified as a linear robot, SCARA robot, articulated robot, parallel robot (delta), or cylindrical robot. There are also automated guided vehicles which are “wheel-based load carriers” that use markers on the factory floor or lasers in order to move around without the need of a human operator.

Highlighted below are some of the different types of industrial robots and their benefits.

Types of Industrial Robotics

| Type of Industrial Robot | Typical Applications | Photo | Description | Benefits |

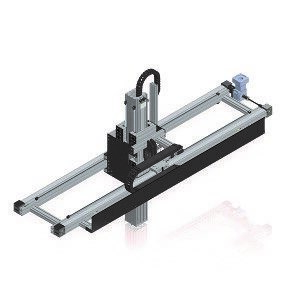

| Linear Robot | • Sorting • Palletizing • Assembly • Pick and Place • Packaging |

| Moves in a straight line and features two to three axes | •Accuracy • Quick Reprogramming |

| SCARA Robot | • Pick and Place • Assembly • 3D Printing • Dispensing • Engraving • Handling • Screw Driving/Tightening |

| Selective Compliance Assembly Robot Arm (SCARA) that can extend and retract like a human arm | • Accuracy • Speed • Compact |

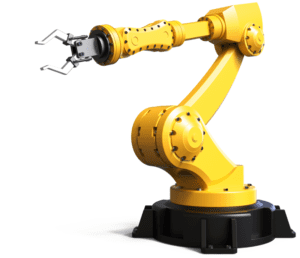

| Articulated Robot | • Welding • Assembly • Part Transfer • Packaging • Machine Loading • Palletizing • Pick and Place • Material Handling |

| Features four to six axes which provides a wide range of movement | • Accuracy • Speed • Wide range of movement |

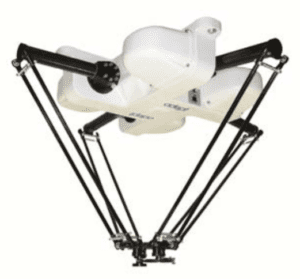

| Parallel Robot | • Flight Simulation • Automobile Simulation • Milling Machine • Picking and Placement |

| Features a single base with multiple linear actuators | • Accuracy • Reliability • Multiple Applications |

| Cylindrical Robot | • Welding • Assembly • Palletizing • Packaging • Injection Molding • Machine Handling |

| Features a rotary joint and a prismatic joint for angular motion around a joint axis | • Speed |

| Automated Guided Vehicles | • Raw Material Handling • Part Delivery • Finished Goods Movement • Warehouse Distribution |

| Warehouse vehicle that can move materials and is controlled by a computer | • Speed • Safety • Efficiency • Cost Effective |

How do industrial robots work?

Industrial robots operate in order to perform specific tasks or functions based on their structure and software program. Depending on the type of robot, an industrial robot will perform its functions by using arms, actuators or wheels. The software program of the robot will determine the action it performs and can be changed between programs if the robot is designed to perform many tasks.

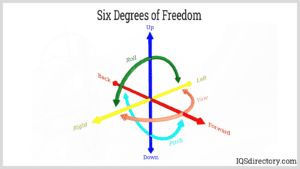

The most common type of industrial robot will feature an arm that rotates around one or multiple joints or links in order to move. The arms can typically move along six axes: left/right, up/down, backward/forward, yaw, pitch, and roll. The more arms and joints the robot has, the greater flexibility it will have along these axes.

The End of Arm Tool (EOAT) or end effector is what actually completes the task that the robot is designed for. The EOAT can vary from task to task and there are even some robots that have interchangeable EOATs for different functions.

Multifunctional Robot Arm

Multifunctional Robot Arm

Power supplies for industrial robotics: Key considerations

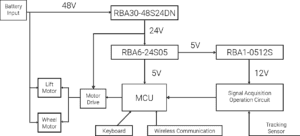

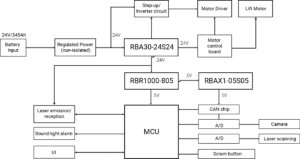

Power supplies play an important role in the proper operation of industrial robotics. Most industrial robots will be powered by a battery source, either chargeable or non-rechargeable. The power supply will help deliver power to different components, like a motor drive or inverter circuit within the robotic circuit. Power supplies may even need to be paired with a specialized component, such as a transceiver, in order to function correctly.

|

|

|

The power supply you choose for your industrial robot will need to be:

- Compact and isolated. Most industrial robots will have significant space and weight constraints you will need to meet when considering a power supply. You’ll also want to ensure there’s no risk of interference between the power supply and the other components in order to meet power supply safety standards.

- Highly efficient. The more efficient your power supply, the lower your energy costs will be. Additionally, an energy efficient power supply will require less maintenance and likely last longer, further reducing your overall operating costs.

- Fast to start up. Minimizing downtime is vital to making the manufacturing process as efficient as possible. A fast start up time for your power supply will help increase productivity and adaptability, while reducing wear and tear and enhancing system responsiveness.

- Low standby power consumption. Whether you’re looking to meet your sustainability goals, extend component lifespan or just ensure compliance with energy efficiency regulations, reducing standby power consumption is key.

There are a number of other questions you’ll want to consider when selecting a power supply for industrial robotics. There may be specific requirements you’ll need to factor in depending on your application – for instance, if your industrial robot will need to operate in high-temperature environments.

Needless to say, finding a robotics power supply that’s tailored to your exact needs is no easy feat. Depending on your specific application, you may need to explore a modified or custom industrial power supply solutions.

Choose Wall Industries for your industrial robotics power supplies

Finding the right power supply for your industrial robot is vital to avoid production slowdowns, additional expenses, and safety problems. But this is easier said than done. There are a wide range of factors to consider, from energy efficiency to size and weight, as well as application-specific issues you might face.

Consulting with industry-leading experts can alleviate some of the challenges in finding the right industrial robotics power supply. At Wall Industries, we’ve been designing and manufacturing industrial power supplies for more than 60 years. Our high-performance team is committed to engineering excellence, so get in touch to find out how we can help you.

You can also visit our industrial robotics product page or take a look at our robotics brief for more information.

Image source:

Image source:

Image source: shutterstock.com

Image source: shutterstock.com Sorting Robot Solution

Sorting Robot Solution Forklift AGVs Solution

Forklift AGVs Solution