Extreme conditions can pose a significant risk to the operational function of power supplies and their associated systems. This is why reliable industrial power supplies are so important in these types of environments. Wall Industries offers a range of standardized and modified power solutions for use in challenging environments.

Our engineers are also experienced in creating ruggedized custom AC DC and DC DC solutions.

This post will focus on the unique design requirements and strategies needed to develop effective power supplies that perform even in the harshest of conditions.

Challenging environments for power supply solutions

Many companies require power supplies which can function in extreme conditions to support their daily operations. To determine if your project will require a power supply like this, you first have to evaluate the environment that your supply will be used in. Some of these conditions to consider are the following:

- Extreme temperatures – Standard power supplies often struggle in environments that are too cold or hot. In the case of the former, components become less conductive which can lead to failure. On the other hand, excessive heat can cause rapid degradation of delicate components leading to failure over time.

- High humidity – Environments with high levels of moisture can cause problems for poorly sealed power supplies in the form of corrosion. This can lead to malfunctions and even complete system failures.

- Frequent shocks and vibrations – Constant vibrations and large shocks cause stress on internal workings, with the most common example being heavy machinery and vehicle power solutions. Excessive forces might also disrupt connections in wiring, possibly resulting in mechanical failure in these components.

- Dust and contaminants – Dirt is a common risk factor in many industrial and outdoor settings. Dust and other contaminants may also be present due to the operations of the business. For instance, military power supplies may be subjected to dust and sand.

Power supply challenges for military applications

Military power supplies must frequently withstand a variety of extreme conditions, arguably making them one of the most common examples of ruggedized power supply system requirements. During exposure to these environments, supplies must be able to deliver efficient and continuous power that meet the demands of connected systems. Military power supply systems must also frequently operate consistently over long periods of time without maintenance. Reliability in the face of these harsh conditions poses unique challenges for military power generation and distribution depending on the nature of the environment.

As a result, military grade DC DC converters and AC DC power supplies are subject to stringent testing to qualify their use. This can make it difficult to implement new designs, although a team of expert engineers with relevant experience in military power supply design can overcome this challenge.

Power supply challenges for aerospace

Power supplies used in aviation, require a number of performance indicators including power density, high efficiency, and high reliability. The are varied and ever-changing.

Power systems for aircrafts must operate in cold, low-pressure, and high altitude environments. On top of this, temperatures and other conditions can change drastically during the course of a flight. In recent years, the need to reduce the environmental impact of air travel has led to research into hybrid electric aircraft. As this continues, we can infer that the challenges for reliability, input and output ranges, and resistance to extreme conditions in power supply solutions will become greater.

Power supply challenges in industrial settings

Typically, industrial facilities operate around the clock due to the implementation of automated processes. Having an industrial uninterruptible power supply is crucial to maintaining operational efficiency. Firstly, there will be many different systems requiring power within the facility, each of which will have their own optimal supply. As such, power supplies must be able to handle the energy requirements of the entire operational infrastructure.

Secondly, there can be lots of variance in environmental factors when it comes to industrial power supplies. This might include excessive dust and dirt, shock and vibration, and temperature changes. The power supply may also get disrupted through other factors, including:

- Faulty wiring

- Ground faults

- Circuit overload

- Power surges

Features of power supplies for extreme environments

In order to function effectively in challenging conditions, power supply systems must have certain protective features. While the most appropriate will depend on the nature of the environment and the operational demands, there are a number of key features which help protect power supplies in extreme environments. These include:

High temperature functionality

One of the key attributes that sets commercial and industrial power supplies apart from each other is their range of operating temperatures. The standardized models in our range of power supplies and converters operate comfortably in a temperature range between -40°C to +85°C. This includes both AC DC and DC DC power supplies.

As mentioned above, sudden and drastic temperature changes can cause electronic systems, including many commercial power supplies, to shut down or incur damage. Oftentimes, industries will have standards in place to ensure the consistent functionality of power supply solutions when sent into harsh environments. For military power supplies, the military standards (MIL-STD) specifies a range of testing which units must undergo before they are fit for use. Some of those standards include:

- Mil-Std-704 – Aircraft Power Standards

- Mil-Std-1399 – Shipboard Standards

- Mil-Std-1275 – Military Vehicle Standards

- Mil-Std-461 – Electro Magnetic Emissions Requirements

- Mil-Std-217 – MTBF Standards

- Mil-Std-810 – Environmental Testing

- Mil-Std-202 – Standardized Test Methods

Robust unit construction

In order to protect internal workings from physical damage, rust, and dust, power supplies must have rugged encasings. Most units for providing power in extreme environments have a high ingress protection (IP) rating. Developed by the International Electrotechnical Commission(IEC), IP ratings assess the resistance of an enclosed space to dust or liquids.

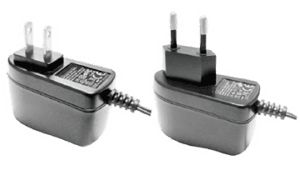

Good examples of robust power supplies can be found in our range of wall mounted power supplies that are designed for an external power source, such as the WMGPSU06X-CC series. The choice of casing material is paramount in protecting power supplies, as well as providing corrosion resistance.

Shock and vibration resistance

Power supplies that can withstand high levels of vibration and significant shocks are often a necessity for challenging environments. This helps circuitry from becoming dislodged and prevents lasting damage to internal components. Specialized mountings, shock-absorbing materials, and resistant coatings can all be protective features in an industrial power supply.

An example from our military power supply systems is the FLEX series of AC/DC power supplies, which have a case material made from ABS, ANC100FR, HI, UL94VO for high impact resistance.

Wide input voltage range

Systems should be able to account for fluctuations in voltage input without changing their output. This is because unpredictable environments are more likely to cause changes to power input. At Wall Industries, our of DC DC converters range from ½ to 1,500 watts and our AC DC power supplies from 1 to 3,600 watts.

Shielding from EMI and RFI

Electromagnetic interference (EMI) and radio frequency interference (RFI) can cause disruption to sensitive electronic equipment connected to industrial power supplies. Wall Industries offers EMI filter cases and transient protectors to maintain functions in the face of electromagnetic disturbance. Options include the following models:

Benefits of a robust power supply

In an ideal design the power supply would be housed in its own enclosure to address heat regulation and dust. Some industrial system applications may not allow for this type of packaging. When systems allow for it, power supplies that have been designed to operate in extreme conditions will benefit from:

- Longer lasting equipment – through resistance to over-voltage, high temperatures, and other potentially stress-inducing factors, robust power supplies help extend the lifespan of equipment by maintaining steady power.

- Avoiding downtime – power supplies that are unaffected by harsh environments are less likely to suffer unexpected shutdowns to help save businesses from the risk of factory line downs and slowed operations.

- Maintaining operational efficiency – robust power supply systems are less likely to go into shutdown and can function without drops in efficiency. This is crucial to uphold operations especially when it concerns power supplies for vehicles and heavy machinery.

- Lessened environmental impact – robust power supplies are more effective at maintaining energy efficiency through a system. Efficient power supplies then enable operations to use less energy overall, resulting in lower emissions.

Wall Industries offers custom power supply solutions that deliver unique specifications for your requirements. . Our projects have included supplies for GPS units, Digital Vehicle Distribution Box (DVDB) systems, ground mobile equipment, military ATX style supplies, and much more. All prototypes are designed according to strict specifications and delivered in as short a timeframe as possible.

Reliable power supplies designed for any conditions

In summary, designing effective power supplies for challenging environments isn’t a ‘one size fits all’ scenario. Robust power supply solutions must be adapted to withstand specific conditions and prevent loss of efficiency or shutdown. Solutions should also ideally be compact, allowing for seamless integration with other systems in the application.

Our team has an intimate understanding of the power supply design features which can be used to solve specific challenges brought about by your operations. We have more than 60 years’ experience in providing power converters and supplies for use in extreme environments.

Whether you require off-the-shelf power solutions or a fully customized design with added extras, our team has you covered. Wall Industries is committed to engineering and manufacturing excellence in even the most challenging environments. Get in touch to discuss how we can help with your next project.

You can also view our full range of military power supply products for more information.