From military electronics to industrial automation controls and transportation systems, external power supply devices are essential for providing reliable power in harsh environments.

Due to different mountings and exposure to outside environmental conditions, external power supplies often exhibit different design features from internal ones. As such, engineers should take a different approach when analyzing external and internal power supplies.

This whitepaper explores the defining characteristics, use cases, and key design considerations for external power supplies, while also outlining relevant environmental standards and showcasing industry-proven solutions from Wall Industries.

External Power Supply Main Uses

External power supplies are self-contained units that supply AC DC power to equipment via cabling and/or dedicated input ports. The ability of external power supplies to use space efficiently and ensure reliable delivery of power makes them a valuable option for many applications.

External power supplies are commonly used in systems where space, heat dissipation, or modularity are key concerns. Common application areas include:

- Military & Aerospace: Tactical radios, GPS receivers, field communication kits

- Industrial Automation: Sensors, small controllers, panel displays, instrumentation. Computer chargers and other portable electronic requirements

- Transportation: Railway control systems, signal repeaters, ticketing terminals.

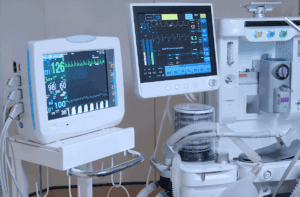

- Medical Equipment: Portable monitors, diagnostic devices

- Telecom & Networking: Modems, routers, network switches

What to Consider When Choosing an External Power Supply

When selecting an external power supply, design factors should be considered that reflect the intended application. Focusing on these areas will help determine whether the end application requirements can be met by an off-the-shelf product or if a custom solution will be needed.

1. Output Power and Voltage Ranges

External power supplies must be able to provide output power and voltage levels that meet the operational requirements of any end user systems. Choosing a supply with insufficient power, overvoltage, or instability can damage system components and compromise the functionality of devices connected to the power supply.

Key points:

- Power Ratings: Ensure the power supply can deliver both the peak and continuous power demands of the load

- Voltage Tolerance: Many industrial and military-grade devices require tightly regulated voltage with minimal ripple or noise

- Multiple Outputs: Some applications may require multiple voltage rails from one external supply

2. Operating Temperature Range

This is particularly important for external power supplies, as they are frequently used in unpredictable outdoor environments where ambient temperatures can change rapidly. This is especially relevant for transport applications, as wind chill becomes a factor when the vehicle is in motion, along with industrial settings with an abundance of heavy machinery.

Key points:

- Typical Industrial Range: −40°C to +85°C is standard for rugged applications, although it is possible to achieve greater thermal resilience if needed.

- Heat Management features: A supply with a wide operating range may include thermal protection, enhanced insulation, or even integrated heat sinks and conduction plates.

- Altitude & Airflow: High altitudes or sealed enclosures impact thermal performance, so it’s recommended to check derating curves.

3. Environmental Protection

All power supplies, but especially those positioned outside, must be resistant to dust, moisture, and liquid. Humidity poses a particularly high risk to electrical components. Although rugged settings also require that power supplies are protected from debris and chemicals.

Key points:

- IP65/IP67 Ratings: Offer high levels of protection for outdoor or washdown environments

- Sealed Enclosures: Ensure longer service life in dusty, sandy, or corrosive conditions

- Compliance: Many sectors (e.g. railway, defense) have mandatory IP level requirements for components to ensure reliability

4. Form Factor

The physical size, shape, and mounting method of the external power supply must align with end application design. A mismatched form factor can lead to installation challenges, thermal management issues, or non-compliance with system layout constraints. When Wall was tasked with producing a custom power supply for electric power grid equipment, one of the biggest challenges was ensuring the system was sufficiently ruggedized for the environment, while at the same time ensuring the design allowed for a versatile input.

Key points:

- Brick vs. Inline vs. Desktop: Choose based on available mounting space and cable routing.

- Connector Type: Barrel, Molex, and screw terminals must all match the system’s input specs.

- Weight & Portability: These are especially important in mobile or transport systems

- Touch temperature: There are normally standards which regulate the outside temperature requirements of these devices such that someone isn’t accidentally burned. This goes directly against the need to cool the supply

5. Environmental and Safety Standards

External power supplies used in harsh environments must meet stringent durability, performance, and efficiency standards. Similarly, they must also be guaranteed not to interfere with the operation of other systems nearby by meeting electromagnetic interference and compatibility requirements. Examples include:

- MIL-STD-810G: Military standard for environmental engineering considerations (shock, vibration, temperature)

- MIL-STD-461: EMC standards for defense systems

- EN50155: Railway applications, including temperature, humidity, vibration, and voltage variations

- IP Ratings: Protection against solid objects and exposure to moisture

These standards ensure power supplies perform reliably in mission-critical applications. Wall Industries’ product offerings are engineered to meet or exceed these requirements.

Wall Industries’ Product Focus

Our power supplies include a wide range of external options that are ideal for various industries.

WMSAW06D Series

Key features:

- Level VI compliance

- Universal 90~264VAC Input Voltage

- Output voltages ranging from 5V to 24V

- UL/cUL, IEC/EN 62368, and FCC safety approvals

- Short circuit, over current, and input protections

DTIPU16 Series

Key features:

- Level VI compliance and Energy Star 2.0 efficiency

- Input Voltage Range of 87V~275VAC

- 12 or 15 W output power

- UL60950-1 and EN 60950-1 safety approvals

- RoHS Compliant

- Three types of AC inlets available – IEC-320-C14 Type A, IEC-320-C8 Type B, IEC-320-C6 Type C

WMEM1024 Series

Key features

- 2.98” x 169” x 1.19”

- 90~264VAC Universal Input Voltage

- 16~36 Watts of output power

- Single outputs range from 5-48VDC

- CB, CE, FCC approvals

- WEEE compliance

DTEA1045 Series

Key features:

- Level VI efficiency

- 100~240VAC input voltage with optional inputs

- LED indication

- Over voltage, over current, short circuit, and optional over temperature protection

- 500pc MOQ

- UL/cUL, CB, CE, FCC, and CCC safety approvals

DTA250 Series

Key features:

- Level VI and EU Tier 1 efficiency compliance

- Built-in DC fan (40 x 40 x 10mm)

- 250 Watts of output power

- Output voltages from 12-48VDC

- 90~264VAC Universal Input Voltage

- UL 60950-1, CSA C22.2-No. 60950-1, TUV EN60950-1, CB IEC 60950-1 safety approvals

External vs Internal Power Supplies

There are many benefits of external power supplies, which can make them more desirable than internal power supplies in certain settings. Common examples include when:

- A fully sealed and IP-rated device is unable to house high-voltage components

- The environment has strict space limitations

- Systems must be easily serviceable

- Energy efficiency and safety standards compliance require design considerations

Most external power supplies are modular and therefore easier to scale due to their positioning options. They also tend to be easier to isolate and cool, along with having greater field replaceability. In cases where internal batteries prove insufficient or run out of charge too quickly, an external power supply can be used to either recharge the batteries or provide a backup power source.

Need a Custom External Power Solution?

External power supplies are a critical component in a wide range of rugged and space-constrained systems. Their modularity, serviceability, and thermal management advantages make them ideal for industrial, military, and transport applications.

By understanding the functional differences, regulatory requirements, and environmental demands associated with power supplies, engineers can select solutions that ensure optimal performance and long-term reliability.

To explore Wall Industries’ full line of external power supplies or to request a custom configuration, contact our team today.