One of the key features in industrial power supplies is a wide operating temperature range. A wide temperature range ensures that the supply, and in turn any end user systems, can function consistently despite large fluctuations in temperature.

Power supplies in industrial settings must have significant thermal resistance due to high ambient temperatures and intense environments of the end user systems they are used in.

This article explores the various design approaches and manufacturing features used to ensure wide operating temperature ranges in industrial power supplies, along with the importance of temperature protections for industrial electrical equipment.

The Importance of Thermal Reliability in Industrial Power Supplies

A wide operating temperature range for industrial power supplies is typically at least -25°C to +75°C, although temperature ranges can be wider depending on the requirements. For instance, our range of high-temperature power supplies offer temperatures ranging from -55°C to +85°C. Most COTS power supplies will have far smaller operating temperature ranges in comparison.

Power supplies must have an operating temperature range that’s appropriate to their systems and operating environment. This ensures the supply doesn’t overheat when in use for extended periods, thereby avoiding losses in efficiency. In industrial settings there are often high ambient temperatures and equipment must run consistently, making high temperature power supplies especially crucial.

Wide operating temperatures also save businesses the cost of replacing and repairing equipment damaged by extreme heat. Power supplies can cause malfunctions in sensitive system components and compromise industrial workflows unless they are properly ruggedized. High temperature power supplies can help eliminate these malfunctions, keeping industrial workers safe.

Designing Power Supplies With Wide Operating Temperature Ranges

When it comes to ensuring thermal resilience in industrial power supplies, the main factor is how the unit has been designed mechanically. During this process, the following should be prioritized:

Cooling

Efficient cooling measures are essential for industrial power supplies to avoid overheating while operating at optimal levels. There are many methods for power supply cooling, including:

- Convection – dissipates heat through the natural convection process. A common example of convection is free air (no forced airflow).

- Conduction – built-up heat in components is dispersed through direct contact with heat sinks.

- Forced air – the cooling system forces cool air around the power supply. This is typically achieved using fans.

High-temperature Components

Arguably, the most significant aspect when designing power supplies to have large temperature ranges is the use of high-temperature components. For example, our in-house brick products can operate to a baseplate temperature of 100°C. All parts of the system construction should be resilient to temperature fluctuations and consistent extremes to prevent inefficiencies and avoid malfunction.

If you aren’t confident that an off-the-shelf solution will meet your requirements, an expertly designed custom power supply will guarantee maximum operating temperature ranges regardless of system components. Many cooling solutions are bulky, so using the right components in your design helps ensure optimal use of space.

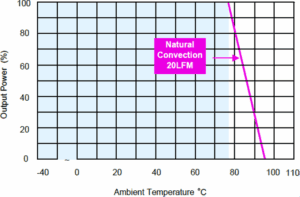

Derating

The most common form of derating, temperature derating, is designed to ensure maximum power supply output by automatically monitoring operating temperatures. As such, you must check that all components in your chosen supply are properly derated for both voltage and temperature. Most industrial DC power supply manufacturers will provide graphs of derating curves so you can visualize whether or not a product is appropriate for your application.

Figure1. Derating curve for DCMAR1 series of DC-DC switching regulators.

Examples of High-Temperature Power Supplies

At Wall Industries, we distinguish our general industrial power supply range from our high-temperature offerings. While all of the former are rigorously tested to ensure adequate temperature protections, below are products specially selected for their thermal resilience at varying voltage input and output ranges.

These 100% burn-in tested desktop power supplies are designed to deliver 40 Watts of continuous power in a 4.21” x 1.85” x 1.19” package. The DTAPU41 series includes free air convection cooling.

- Operating temperature: -40°C to +70°C

- Storage temperature: -40°C to +85°C

If you’re looking for ultra-high levels of isolation in a small SIP package, the LANE-6KV has approval for industrial and medical use. With options for single and dual outputs, these DC-DC power converters are an ideal solution for industrial process controls and instrumentation systems.

- Operating temperature: -25°C to +85°C

- Storage temperature: -50°C to +125°C

This highly efficient and reliable DC-DC power module offers up to 500 Watts of power in a half-brick package ideal for industrial settings. Additional protections include over- and under-voltage, overcurrent, and short-circuit conditions.

- Operating temperature: -40°C to +100°C (standard), -55°C to +100°C (M grade baseplate)

- Storage temperature: -55°C to +125°C

This single-output series sports 2:1 wide input voltage ranges to provide up to 100 Watts of output power for a variety of industrial applications. These models feature various options so they can fit your application requirements, including heat sinks, negative remote on/off controls, terminal block, pin length, and thru-hole inserts.

- Operating temperature: -40°C to +115°C

- Storage temperature: -55°C to +125°C

Potential Challenges in Maintaining Operating Temperatures

All power supplies generate heat when in use, which can add to the overall temperature of the system. This is why we see the difference in power supply temperature range between operating and storage temperatures in datasheets.

External factors that can affect power supply operating temperatures include

- Ambient temperature of the environment

- Load fluctuations

- Heat generated by industrial activities (nearby equipment)

- Enclosed spaces with limited airflow

- Air density (altitude)

- System casing material (plastic or aluminum)

Control and Testing Standards for Operating Temperature

Power supplies for industrial applications are often held to higher standards than those designed for other commercial or domestic use. This is for both safety and performance, as controls ensure the surface temperature of the power supply casing do not get too hot and also protect delicate components.

Depending on the exact application of the power supply in question, you should look for the following compliances:

- UL 60947: Operational and safety standards for industrial control equipment.

- UL 60950-1: Safety standards for mains and battery-powered information technology equipment.

- IEC 60950-1: General safety requirements for information technology equipment (replaced by IEC 62368-1 in most cases).

- IEC 62368-1: Safety requirements for audio/video, information, and communication technology.

- EN 50155: Essential standard for rolling stock in railway applications.

- MIL-STD-810: Military standard for equipment to withstand environmental conditions.

Wall Industries’ Custom Power Solutions

Guaranteeing wide operating temperatures comes down to how the unit is designed mechanically. This means accounting for proper cooling, high efficiency topology, and the use of high temperature components.

For industrial power supplies, thermal requirements are stricter due to potentially conflicting factors. As a result, expert design, thorough testing, and careful planning are needed to source power supplies with appropriate industrial operating temperatures.

Contact us if you have any questions about our range of high-temperature industrial power supplies or our design timeline.