When a power supply is going to be subject to an extreme environment, it is crucial that it has been designed to withstand the harsh conditions it will face. Extreme temperatures, high shock and vibration, dust and particles, and high humidity are all extreme environments that a power supply could be used in. The following features can be implemented into a power supply design to help protect against extreme conditions.

Key features for power supplies in extreme environments:

- Low Temperature Environment: A low temperature environment can cause condensation for a supply and weaken components. Conformal coating, encapsulation, or hermetic sealing can be implemented in order to protect a supply against the effects of low temperature conditions.

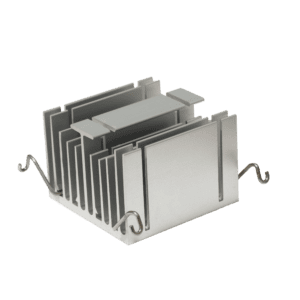

- High Temperature Environment: High temperature environments can cause components to set, deterioration or closure of sealing strips, and overall shortening of the supply’s lifetime. High temperature conditions can be cooled by adding heatsink or fan or utilizing moving air or liquid in the surrounding environment.

- Shock and Vibration: Shock and vibration is likely to occur in a number of extreme environments and it can cause a lot of problems such as components loosening and mechanical failure. Component staking and encapsulation can be implemented in a design to help combat shock and vibration.

- High Humidity and Moisture: Humidity can cause corrosion of metals and delamination of composite materials. To protect a power supply against high humidity, it can be conformally coated or hermetically sealed.

- Wall Industries has had experience designing power supplies for high humidity and moisture environments. Our custom switching power supply for use in a commercial water application maintained high efficiency and reliability while being used in a high moisture environment.

- Dust and Sand: Dust and sand in an environment can cause abrasion and of surfaces, degradation of circuits, obstruction or clogging of openings or filters, and reduction of thermal conductivity. Supplies can be protected from sand and dust by a hermetic seal or conformal coating.

Wall’s custom power supply for electric power grid equipment is one example of a supply we have designed for these types of extreme environments. This supply had to be hardened against the many challenging environmental factors it would face during use. Our case study covers all the details of this robust power supply.

No matter what extreme environment your power supply may face, there is a design solution to help keep it running efficiently. Wall Industries is committed to engineering and manufacturing excellence in even the most challenging environments. Get in touch to discuss how we can help with your next project.