1. Shock Electrodialysis to Treat Nuclear Wastewater

Nuclear wastewater can be very dangerous and hard to treat and dispose of. Large volumes of water are being used in nuclear power plants for cooling purposes, resulting in large volumes of water that need to be disposed of because it is contaminated with radioactive isotopes.

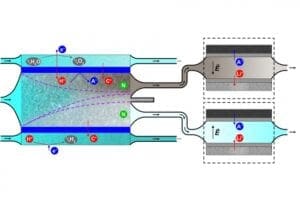

A team at MIT has come up with a new method to reduce the high volume of contaminated water that needs to be disposed: shock electrodialysis. In this method, an electrical field is used to create a deionization shockwave in the water. This shockwave forces all of the electrically charged particles to one side of a tube containing charged porous material. Since the charged particles are on one side of the tube, it easier to separate contaminants, in this case isotopes of cobalt and cesium, and properly dispose of them. The remaining clean water can be recycled for use in the reactor.

This method was originally tested as a method of removing salt from water, but it was realized that it could be adapted to other specific applications. According to Martin Bazant, a member on this research crew:

“No other practical, continuous, economic method has been found for separating out the radioactive isotopes of cobalt and cesium, the two major components of nuclear wastewater.”

Image Source: news.mit.edu

The diagram illustrates the process, in which contaminated water enters from the left, and is subjected to an ionic shockwave (depicted by dashed purple lines) that concentrates radionuclides of cesium and cobalt on one side (darker area at top) from purified water (light-colored lower area). The clean water can be recirculated to the reactor, while the concentrated contaminants can be safely disposed of.

Source: https://news.mit.edu/2019/remove-contaminants-nuclear-plant-wastewater-1219

2. Droplet-Based Electricity Generator

Have you ever considered using raindrops as a source of kinetic energy or possible power source? A team at the City University of Hong Kong (CityU) has done just that. They have developed a new droplet-based electricity generator (DEG), as a new way of efficiently generating electricity from the kinetic energy of raindrops.

They have created a new system featuring a structure similar to a field-effect transistor (FET) that can help increase energy-conversion efficiency and has “high instantaneous power density”. In this system, drops of water land on the electret material PTFE, which means it has a quasi-permanent electric charge to it. The addition of the PTFE is essential, since it gives high-density surface charges a chance to reach saturation, rather than create a bottleneck of low charge density. The PTFE is deposited as a film on an aluminum electrode and an indium tin oxide (ITO) electrode.

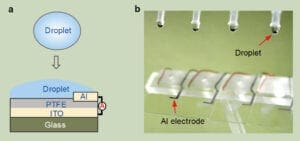

Image Source: City University of Hong Kong / Nature

Fig a is the schematic diagram of droplet-based electricity generator (DEG). Fig b is the optical image showing four parallel DEG devices fabricated on the glass substrate.

The PTFE/ITO surface generates, stores, and inducts the charge that is created by falling droplets.

According to the article from CityU:

“When a falling water droplet hits and spreads on the PTFE/ITO surface, it naturally “bridges” the aluminum electrode and the PTFE/ITO electrode, translating the original system into a closed-loop electric circuit.”

This design allows for a high density of surface charges to build-up on the PTFE as more and more droplets land on it. As the number of charges grows, water spreads and continues to connect the electrodes until all of the charges can be released as an electrical current.

One of the research leaders on this project, Processor Wang, stated that

“Our research shows that a drop of 100 microlitres (1 microlitre = one-millionth litre) of water released from a height of 15 cm can generate a voltage of over 140V. And the power generated can light up 100 small LED light bulbs.”

As previously mentioned, this droplet-based generator is effective due to the kinetic energy of the falling water, not additional energy being applied. This means that this technology will be most useful in applications with moving water, such as ferries, coastlines, water bottles, and umbrella surfaces. Wang believes that in the future, this type of technology could be installed in applications where liquid is in contact with solids.

3. EcoVolt by Cambrian Innovation

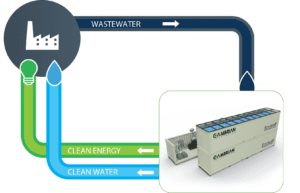

Treating wastewater in the food and beverage industry can be an inefficient and energy-intensive process for a lot of facilities. Cambrian Innovation introduced a bioelectrically enhanced wastewater treatment system called “EcoVolt” in 2013 to help improve these wastewater applications in industrial environments.

The EcoVolt works by using electromethanogenesis. Microbes that are already electrically active to help stabilize the process of wastewater treatment, while also generating clean energy. The “electricity-generating organisms” help convert the pollutants in wastewater into electricity that can be funneled to a circuit, back into an electrode, where electricity and CO2 are converted into methane fuel by a different set of microorganisms. This resulting fuel can then be used for heat or clean power on site.

Image Source: cambrianinnovation.com

Image Source: cambrianinnovation.com

This anaerobic wastewater treatment system helps food and beverage companies accommodate for the fluctuations in production cycles, BOD loadings, and wastewater flows. It has been used in breweries, dairy operations, wineries, and other food and beverage companies. The team at Cambrian Innovations has stated that

“EcoVolt is a robust, end-to-end, anaerobic wastewater treatment solution that can operate across a range of biological oxygen demand (BOD) loadings and wastewater volumes.”

Source: https://cambrianinnovation.com/ecovolt-now-commercially-available/

4. Salt Water Chlorine Generators for Pools

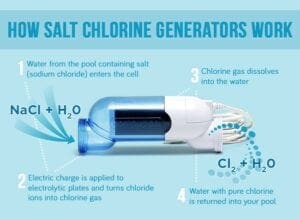

In both commercial and residential pools, using salt water chlorine generation has been increasing in popularity. They are becoming popular due to the fact that they can generate their own chlorine, and the chlorine that they generate is typically cleaner than the chemicals that can be bought at a store. Innovative technology involving electricity and electrolytic plates play a key role in helping salt chlorine generators work. Wall Industries has experience designing this type of advanced technology; you can read more about our experience here.

A salt water chlorine generator uses electrolysis to turn salt into hydrochloric acid and sodium hypochlorite. Chlorine gas is then created as the salt water passes through a salt cell and an electronic current causes the necessary chemical reaction. The pool water is then chlorinated and sanitized. The control plate of the generator helps control the level of chlorine the pool is getting and also provides the electricity to metal plates used in the process.

Image Source: PoolSupplyWorld.com

See how Wall helped create a supply for a commercial chlorination application in our Commercial Water Case Study.

Source: https://poolcareguy.com/salt-water-chlorine-generation/

5. Biobooster Treatment Process from Grundfos

The wastewater from hospitals can be a huge challenge to treat, as it can contain traces of harmful chemicals, viruses, bacteria, and other dangerous substances that have to be treated carefully and thoroughly. Hospital wastewater is generally sent to public treatment facilities that are not equipped to deal with this type of dangerous wastewater.

Grundfos was tasked with finding a better solution to this problem of hospital wastewater treatment, specifically for the Herlev Hospital in Denmark. They created a BioBooster wastewater treatment to treat the hospital wastewater in three steps.

According to Grundfos.com the plant involves “biological purification processes as well as a system of ceramic filtration membranes and a final ‘polishing’ with activated carbon and ozone.” Each module of this system can be removed or changed to accommodate the needs of the facility. Once the whole process is complete, the remaining “sludge” from the system with the dangerous chemicals and pathogens is dried and sent out for incineration.

Image Source: Grundfos.com

PHOTO: Part of the Grundfos Biobooster treatment process involves sending the hospital effluent at very high pressures through a series of membrane filtration units.

Image Source: Grundfos.com

PHOTO: The BioBooster system purifies hospital wastewater in three steps.

Three factors lent themselves to the success of this program:

- The proximity of the plant to the hospital.

- The compact layout of the system.

- Targeting substances that are specifically in hospital water.

The actual Biobooster treatment system was housed next to the hospital, which was essential since the facility was only treating water from the hospital, no public water. The facility also only contains 4 to 5 modules, making it a very compact system. Flowing water from the hospital can be sent through these membrane filtration units at very high pressures, rather than having to travel through long pipes to a municipal facility. In contrast to a municipal facility, the Biobooster process can also specifically target the substances found in hospital water that could fall to the wayside in public water treatment.

6. Ultraviolet Germicidal Irradiation

Though ultraviolet germicidal irradiation (UVGI) is not an entirely new concept, the way it has recently been adapted for commercial and industrial water disinfection is impressive. UVGI is a method of disinfection that utilizes shortwave ultraviolet-C (UV-C) radiation to kill or inactivate microbes. The radiation from these shortwaves damages the DNA of the microbes and renders them unable to replicate. Not all microorganisms can be destroyed by the UV light, however, and how many destroyed depends on how intense the light is.

Though UVGI can be used to disinfect air and surfaces, water disinfection applications have had a lot of success. UV water treatment systems have been seen in everything from household pools to large-scale municipal treatment plants.

UV water treatment can be classified as either Class A or Class B. According to water-research.net, Class A systems “must have an ‘intensity & saturation’ rating of at least 40,000 uwsec/cm2 and possess designs that will allow them to disinfect and/or remove microorganisms from contaminated water. Affected contaminants should include bacteria and viruses.”

Water-research.net also says that Class B systems “must have an ‘intensity & saturation’ rating of at least 16,000 uw-sec/cm2 and possess designs that will allow them to provide supplemental bactericidal treatment of water already deemed ‘safe’.”

Image Source: Shutterstock

The UV method of treatment is a unique method of disinfection does not use harmful chemicals and can help combat viruses and bacteria. Is this a method you would consider using?

Sources:

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2789813/

https://www.water-research.net/index.php/water-treatment/water-disinfection/uv-disinfection

7. DyeCoo Textile System

Textile and fabric dying can be very reliant on water. According to greenbiz.com, 25-40 gallons can be used for every two pounds of fabric that is dyed. In order to reduce the amount of water used in textile dying, DyeCoo found a solution in a carbon-based process.

Image Source: greenbiz.com

DyeCoo has a system called the DyeOx that consists of three vessels and uses reclaimed CO2 to carry dye for textiles. The system first pressurizes CO2 to the point that it is supercritical (SC-CO2) and in liquid form. This liquid CO2 is then used to dye textiles, rather than several gallons of water. This is all performed in a closed loop system, resulting in 95% of the CO2 being recycled and no wastewater to treat. This method offers an impressive and unique alternative that helps save water compared to the traditional ways of dying textiles.

Source: http://www.dyecoo.com/co2-dyeing/

https://www.greenbiz.com/blog/2014/08/04/10-companies-innovating-water-making-waves-water-innovation

8. Deionization Devices for Desalination of Water

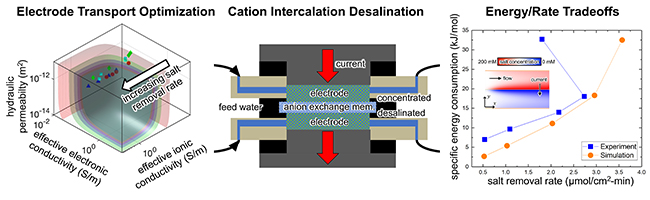

Desalinating ocean water has long been a proposed solution to the issue of diminishing sources for clean water. An assistant professor, Kyle Smith, at the University of Illinois has been researching a new way to desalinate saltwater. His method “involves deionization devices that can reversibly store and release cations using intercalation materials” according to an article the University wrote on the topic. These intercalation materials are usually used in rechargeable batteries and face the challenge of cycling with fast rates of electron, ion, and fluid transport in this system.

Image Source: Kyle Smith

Smith’s team created optimized electrodes with Prussian Blue analogue particles that were used in a cation intercalation desalination (CID) cell containing symmetric electrodes. The resulting salt removal rate they saw was almost 10 times more than past CID demonstrations.

This is not the first desalination project Smith has taken on. In 2016, he created a “saltwater-filled battery with electricity running through it” that was able to deionize water using minimal energy. He also created another battery-like device in 2017 that could remove sodium ions, potassium, calcium, and magnesium from saltwater.

Source: https://mechanical.illinois.edu/news/illinois-engineer-continues-make-waves-water-desalination

9. Flexible Aqueous Sodium-Ion Batteries

Wearable technology is a constantly growing industry. An issue that developers run into time and time again is safety, as a lot of the energy storage systems in these devices are based on electrolytes that are toxic or corrosive which can be dangerous if leaked onto skin.

In 2017, a team in China developed a safe solution to this problem: flexible belt- and fiber-shaped aqueous sodium-ion batteries (SIBs). The SIBs consist of various aqueous electrolytes containing Na+, a Na0.44MnO2 cathode, as well as a nano-sized NaTi2(PO4)@C anode. The combination of these elements give the SIBs high flexibility, high volumetric energy and power density, and a long life. This will ultimately result in a wearable that much safer than the usual toxic solutions typically used in flexible batteries.

The team also discovered that even if cell-culture medium or saline is used as the electrolyte, the SIBs still operate properly. This indicates that there could be potential for this system to work in implementable electronic devices. They could also be used in biological and medical fields due to the electrochemical deoxidization function of the electrodes in the aqueous electrolytes containing Na+.

Source: https://www.sciencedirect.com/science/article/pii/S2451929417302176

10. Hydrodynamic Cavitation for Fluid Applications

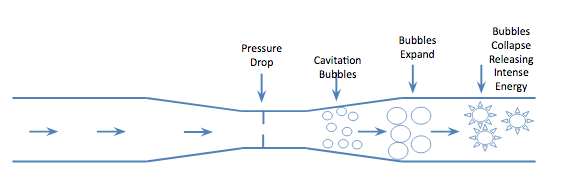

Hydrodynamic cavitation is the process that uses turbulent pressure to create very small bubbles that expand and eventually implode. This implosion creates high temperature and pressure that can intensify many processes.

Image Source: voltekwater.com

Hydrodynamic cavitation has been used in a variety of fluid applications including oxidization, water treatment, extraction, mixing, and heating. These cavitation systems can be very beneficial as they are non-damaging to equipment, are easily scalable, and typically use less energy.

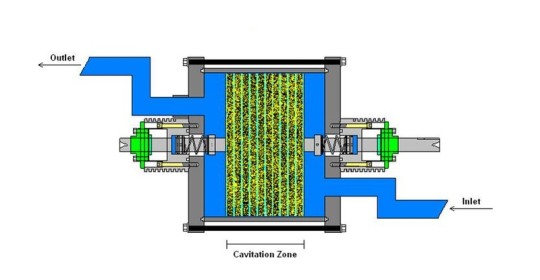

For example, Hydro Dynamics, Inc. has a Shockwave Power Reactor (SPR) that uses controlled cavitation for fluid processing among a variety of industries. In their unit, liquid is fed into the heart of the device, which contains a unique spinning rotor. The spinning of the rotor creates the hydrodynamic cavitation within the cavities of the rotor. As the bubbles from the cavitation are created, expand, and implode, shockwaves are “given off into the liquid” and the liquid is now energized and can be used in several applications.

Image Source: hydrodynamics.com

The hydrodynamic cavitation proves to accelerate processes, improve product yield, reduce product downtime, and provides more efficient mixing.

Source: https://www.kinetic-reactor.com/kinetic-technology/

https://www.voltekwater.com/hydrodynamic-cavitation

https://www.hydrodynamics.com/cavitation-technology/

11. Single-Catalyst Water Splitter

Hydrogen fuel, typically created from natural gas, is often suggested as an “emissions-free alternative to gasoline.” Scientists at Stanford University have discovered a low-cost way to generate this valuable hydrogen fuel by splitting water.

Water splitting devices in the past have been less efficient and have used expensive and/or rare metals. They operated by applying a low-voltage current to two electrodes embedded with a catalyst, platinum and iridium or nickel and iron, that were submerged in a “water-based electrolyte.” Applying the voltage resulted in a catalytic reaction that divided the hydrogen and oxygen molecules in the water (H2O). The molecules were released as bubbles on the electrodes, hydrogen on one and oxygen on the other. Devices like these need a barrier between the electrolytes, since one is acidic, one is alkaline, in order to keep the pH stable. This also barrier also adds to the cost of the device.

The new water splitter operates similarly to these old devices, but only uses one catalyst of nickel-iron oxide for each of the electrodes. Nickel-iron is not only cheaper, but since there is only one type of catalyst, there is also no need for the barrier between the electrolytes as the pH will stay uniform without it. The team used lithium-induced electrochemical tuning, which is typically used in battery research, to discover the efficient catalyst.

Image Source: L.A. Cicero

Unlike conventional water splitters, the device developed in Associate Professor Yi Cui’s lab uses a single low-cost catalyst to generate hydrogen bubbles on one electrode and oxygen bubbles on the other.

Hoatian Wang, lead author of the study, claims that

“This bi-functional catalyst can split water continuously for more than a week with a steady input of just 1.5 volts of electricity. That’s an unprecedented water-splitting efficiency of 82 percent at room temperature.”

Source: https://news.stanford.edu/2015/06/23/water-splitter-catalyst-062315/

https://web.stanford.edu/group/cui_group/papers/Zhiyi_Cui_ADVMATER_2018.pdf