Railway DC DC Converters

Railway DC DC Power Converters

Wall Industries offers a comprehensive range of high-quality DC DC power converters designed for railway applications. Our standard railway products are engineered to meet the strict requirements of the railway industry, including compliance with EN 50155 and EN 50121-3-2, and offer high efficiency, high reliability, and a wide input voltage range.

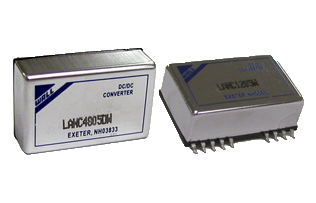

Products are available in quarter-brick, half-brick, and full-brick packages, as well as DIN rail mounted packaging. Many of our railway series come with value-added options such as heat sinks, terminal blocks, and conformal coatings. With output power available from 6 to 1000 watts, our railway converters are ideal for a wide range of applications, including onboard train systems, signaling systems, and trackside equipment.

Their high isolation voltage and wider temperature range make them well-suited to the demanding environments encountered in railway applications. Explore our range of DC DC power converters to find the right solution for your railway power needs.

| Series | Input Range |

Input Voltage |

Output Voltage |

No. Outputs |

Output Power (W) |

|

|---|---|---|---|---|---|---|

DCRUW6

|

Input Range: 40~160 | Input Voltage: 110 | Output Voltage: 5, 12, 15, 24, ±5, ±12, ±15 | No. Outputs: S, D | Output Power (W): 6 | Get a Quote |

DCURB06

|

Input Range: 9-36, 18-75 | Input Voltage: 24, 48 | Output Voltage: 3.3, 5, 9, 12, 15, 24, ±5, ±12, ±15, ±24 | No. Outputs: S, D | Output Power (W): 6 | Get a Quote |

LANCUW8

|

Input Range: 18-75, 43-160, 9-36 | Input Voltage: 24, 48, 110 | Output Voltage: 3.3, 5, 12, 15, ±5, ±12, ±15 | No. Outputs: S, D | Output Power (W): 8 | Get a Quote |

DCRHW10

|

Input Range: 40~160 | Input Voltage: 110 | Output Voltage: 3.3, 5, 12, 15, 24 | No. Outputs: S | Output Power (W): 10 | Get a Quote |

DCURB10

|

Input Range: 9~36, 18~75 | Input Voltage: 24, 48 | Output Voltage: 3.3, 5, 9, 12, 15, 24, ±5, ±9, ±12, ±15, ±24 | No. Outputs: S, D | Output Power (W): 10 | Get a Quote |

DCREDUW20

|

Input Range: 9-36, 18-75, 43-160 | Input Voltage: 24, 48, 110 | Output Voltage: 3.3, 5, 12, 15, ±12, ±15 | No. Outputs: S, D | Output Power (W): 14.8, 20 | Get a Quote |

RDW15

|

Input Range: 9~36, 18~75, 36~160 | Input Voltage: 24, 48, 110 | Output Voltage: 3.3, 5, 12, 15, 24, ±5, ±12, ±15, ±24 | No. Outputs: S, D | Output Power (W): 15 | Get a Quote |

DCURB15

|

Input Range: 9~36, 18~75 | Input Voltage: 24, 48 | Output Voltage: 3.3, 5, 12, 15, 24 | No. Outputs: S | Output Power (W): 15 | Get a Quote |

DCURB

|

Input Range: 9~36, 18~75 | Input Voltage: 24, 48 | Output Voltage: 3.3, 5, 6, 12, 15, 24 | No. Outputs: S | Output Power (W): 20 | Get a Quote |

DCRW20

|

Input Range: 40~160 | Input Voltage: 110 | Output Voltage: -24, -15, -12, 12, 15, 24 | No. Outputs: D | Output Power (W): 20 | Get a Quote |

What is a Railway DC to DC power converter?

A railway DC to DC power converter is an electromechanical device that is purpose-built for the applications within the railway industry. It converts a source of direct current from one voltage to another. DC to DC power converters can be used to step down voltages from a high power voltage to lower voltage, they can also be used to match loads to a power supply, or isolate primary and secondary circuits.

From a broad perspective, railway DC to DC power converters can be divided into boost converters and step down converters. Boost converters are used to step up DC voltage, whereas step down converters are used for the opposite purpose. These DC to DC power converters are uniquely designed to function in railway applications, with extra care paid to the environmental conditions that they are used in, the need for hard-wearing resistance and overall longevity.

How does a Railway DC to DC boost converter work?

A railway DC to DC boost converter is sometimes referred to as a ‘step-up converter’ and is a class of switched-mode power supply. A boost converter consists of an inductor, a semiconductor switch, a diode and a capacitor. The basic design for a boost converter was originated in the 1960s; they were initially designed for use in aircraft which is why they’re known for being compact and efficient.

The key principle behind how boost converters work is the inductor’s nature to resist changes in current. It does this by either increasing or decreasing the energy stored in the inductor magnetic field. The inductor responds to the sudden turning off of the current from the semiconductor switch by generating a larger voltage with the opposite polarity of the voltage source, using the energy stored in the magnetic field to maintain the current’s flow.

How does a Railway DC to DC step down converter work?

A railway DC to DC step down converter works in a similar way to that of a step up converter. The converter takes the current and passes it through a switching element which turns the signal into a square wave. This wave is then passed through another filter, turning it back into a DC signal of an appropriate voltage.

What does a Railway DC to DC power converter do?

Railway DC to DC power converters are specifically designed and built to convert DC battery voltages into lower voltages. Railway rolling stock uses a DC power distribution system which relies on the use of batteries to maintain power in the event of a generator failure. DC to DC power converters ensure that current is of the correct voltage and power can be sustained to important systems.

What are the EN50155 Compliance to Railway Standards?

All electronic equipment that is installed on trains must comply with the EN50155 Compliance to Railway Standards. Electronic equipment that is used on rolling stock are put under significant strain are expected to operate for 24 hours a day, 7 days a week for upwards of 30 years without failure.

The EN50155 regulations comprise a document of 44 pages which also make reference to 36 other related standards. The EN50155 can be broken down into a few simple sections which outline the baseline expectations of any railway DC to DC power converter.

Resistance to harsh environmental conditions

In order for DC to DC power converts to function properly, they need to be suitably designed to withstand the conditions that they are placed in, as well as adhere to the rigorous standards that are expected of electronic equipment that is being used for railway applications.

Extreme temperatures

In order for power converters to adhere to the EN50155 regulations they must be proven to operate over a wide temperature range from -40°C to +85°C, however, only some of the parts need to operate within this range for 10 minutes during startup. Efficiency is also important and equipment should work at an efficiency of 85% or higher. This efficiency must be proven over a range of voltage and load conditions and is usually managed via a heat sink setup.

Shock and vibration

The EN50155 makes specific reference to a separate standard when referring to shock and vibration. The BS EN 61373:2010 is a specific set of regulations that relate to shock and vibration tests that should be conducted on rolling stock equipment used in railway applications. The standard covers the requirements for random vibration and shock testing items of electronic equipment.

Humidity

The EN50155 makes specific reference to standards related to humidity. Electronic equipment must be able to function in an average humidity of 75% followed by 30 consecutive days of 90% relative humidity. In most cases, this requires DC to DC power converters to be encased in a watertight housing.

Dust and atmospheric pollutants

During the course of its life, electronic equipment used for railway applications can be exposed to a range of atmospheric pollutants including conductive dust, oil mist, salt spray and sulphur dioxide. Railway DC to DC power converters should be housed in a resistant casing, ensuring that these pollutants do not gain entry and affect performance.

Electromagnetic compatibility

Railway DC to DC converters must operate correctly even when subjected to disruptive electromagnetic environments. Strong magnetic fields are generated by electric motors and transformers, not to mention interference that is emitted by pantographs.

The EN50155 requires that all railway DC to DC converters should not be adversely affected by conducted or radiated interference, nor should they emit radio frequency interference in excess of the levels as defined in the supporting regulation EN 50121-3-2.

Type approval test

The EN50155 lists a series of supporting tests that should be conducted before electronic equipment can be said to be compliant these include:

- Visual inspection

- Performance test

- Low temperature operation test (minimum operating temperature for 2 hours)

- Dry heat test (maximum operating temperature for 6 hours)

- Confirmation of operation over the full input voltage range

- Surge, ESD and transient tests

- Electrical insulation test

- Damp heat cyclic test

- Water-tightness

- Production stress screening

- Low temperature storage (-40°C for 16 hours)

What to consider when selecting a DC to DC Converter for Railway applications?

Input voltage range

The power supply is a key component for railway DC to DC converters and a number of different voltages are used on rolling stock. The EN50155 makes specific reference to 24, 48, 72, 96 and 110VDC. Typically, DC to DC converters use a 4:1 input voltage range such as 10-40V, 18-72V and 40-160V.

Case size

Case sizes for DC to DC power converters vary and are typically referred to as bricks, half-bricks or quarter-bricks and each is associated with a standardised size. Full-bricks measure 4.6 x 2.4 x 0.5 inches, a half-brick measures 2.3 x 2.4 x 0.35 inches, and a quarter-brick measures 2.3 x 1.45 x 0.35 inches.

Who can design your railway DC DC converters? Why is Wall the best choice?

Wall Industries have decades of experience designing and manufacturing high-quality DC to DC converters for the railway industry. All our products offer the high reliability and efficiency that are expected of converters in this industry and also have a wide input voltage range. All our series are available with a number of value-added options, including heat sink, terminal block, and conformal coating.

If you can’t find a product that is right for your needs, we can offer custom solutions that meet your exact requirements. We have the ability to manufacture high and low volume orders, so you can rely on us to deliver your railway DC to DC converter in a reliable manner.

Does railway equipment use AC or DC power?

Railway equipment can use either AC or DC power, depending on the type of railway system and application. Traditional railway systems tend to use DC power, whereas modern railway systems with high speed trains tend to use AC power. Subway trains tend to use DC power as they typically operate at lower speeds.

How do I choose the right railway power supply?

When choosing the right railway power supply, it’s important to consider a number of factors including compliance with EN 50155 and EN 50121-3-2, high efficiency, high reliability, and a wide input voltage range. Other specifications that may need to be considered include, shock and vibration, voltage spikes, and dirty power sources.

Do I require isolation for my Railway power supply?

Whether or not your railway power supply requires isolation depends on the nature of the application. Many Railway applications are susceptible to being exposed to shock, vibration, temperature and humidity extremes, therefore isolation may be required.

How do I know if a power supply is safe to use for Railway applications?

If your power supply is safe to use for Railway applications, it will be built to meet important Railway safety standards including EN 50155, EN 61373, EN 50121-3-2 and EN 45545-2.

Are DIN Rail power supplies used for Railway applications?

Din Rail page is marked as no content/set to remove. This one is not going to be removed, just the subcategories of the Level VI page were removed.